wire edm machine working principle

Working Principle of Electrical Discharge Machining Process. Working Principle of Electrical Discharge Machining Process.

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

As the spark jumps across the gap materia.

. For the EJ251 and EJ252 engines the four valves per cylinder were actuated by. No actual contact is made between the. One-piece solid valve lifters.

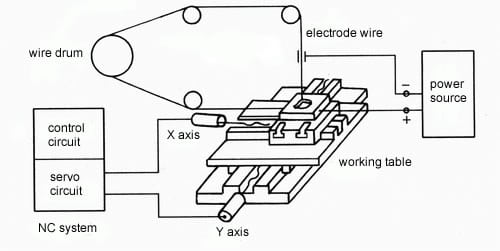

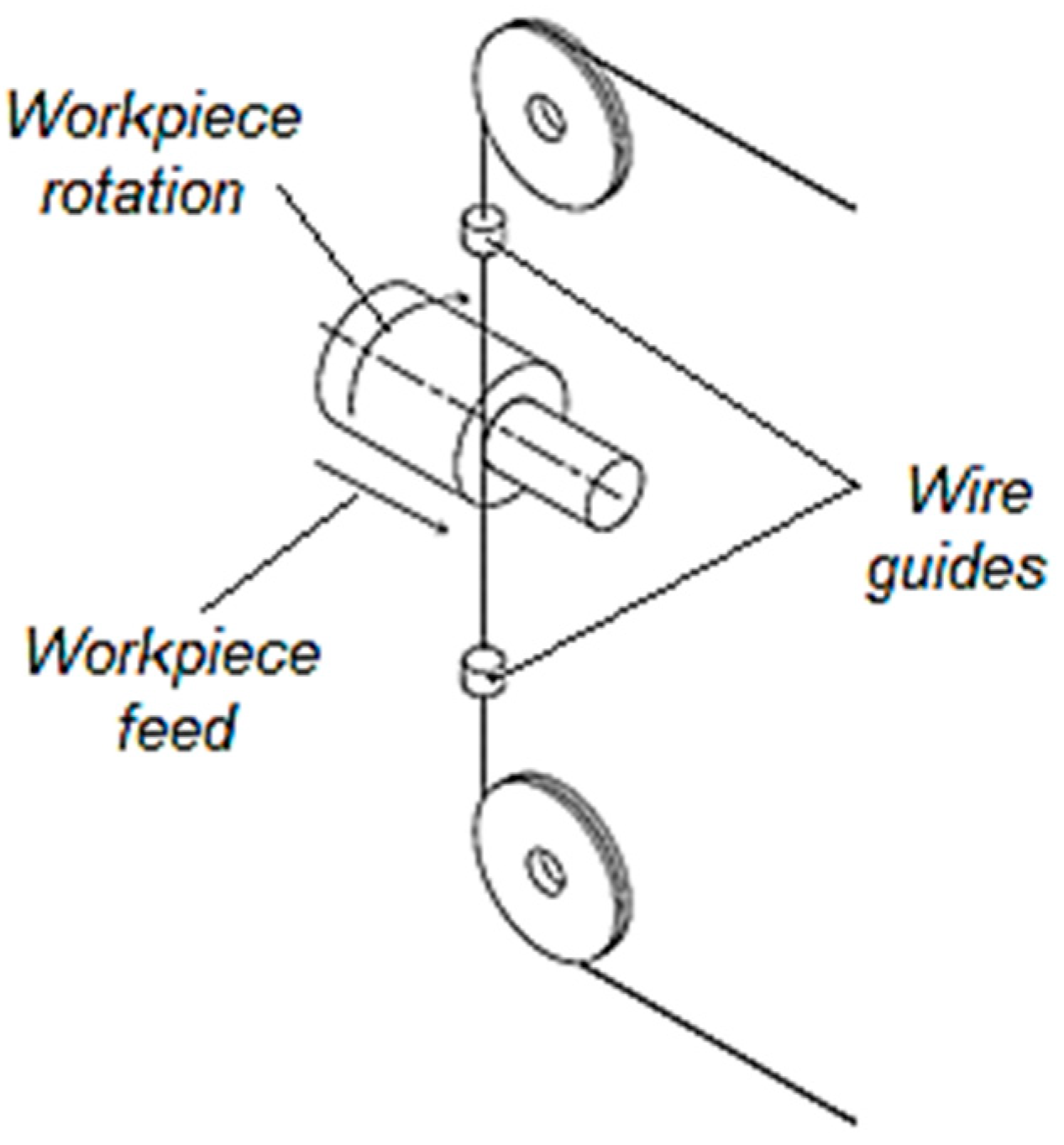

The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting. The workpiece is fixed in the dielectric container using a fixture. Wire edm machine working principle Tuesday.

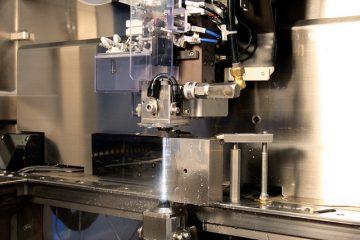

Ad Faster processing times superior surface finishes for the most complex part geometries. Makino EDMs have a streamlined and efficient interface that helps work get done faster. Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin.

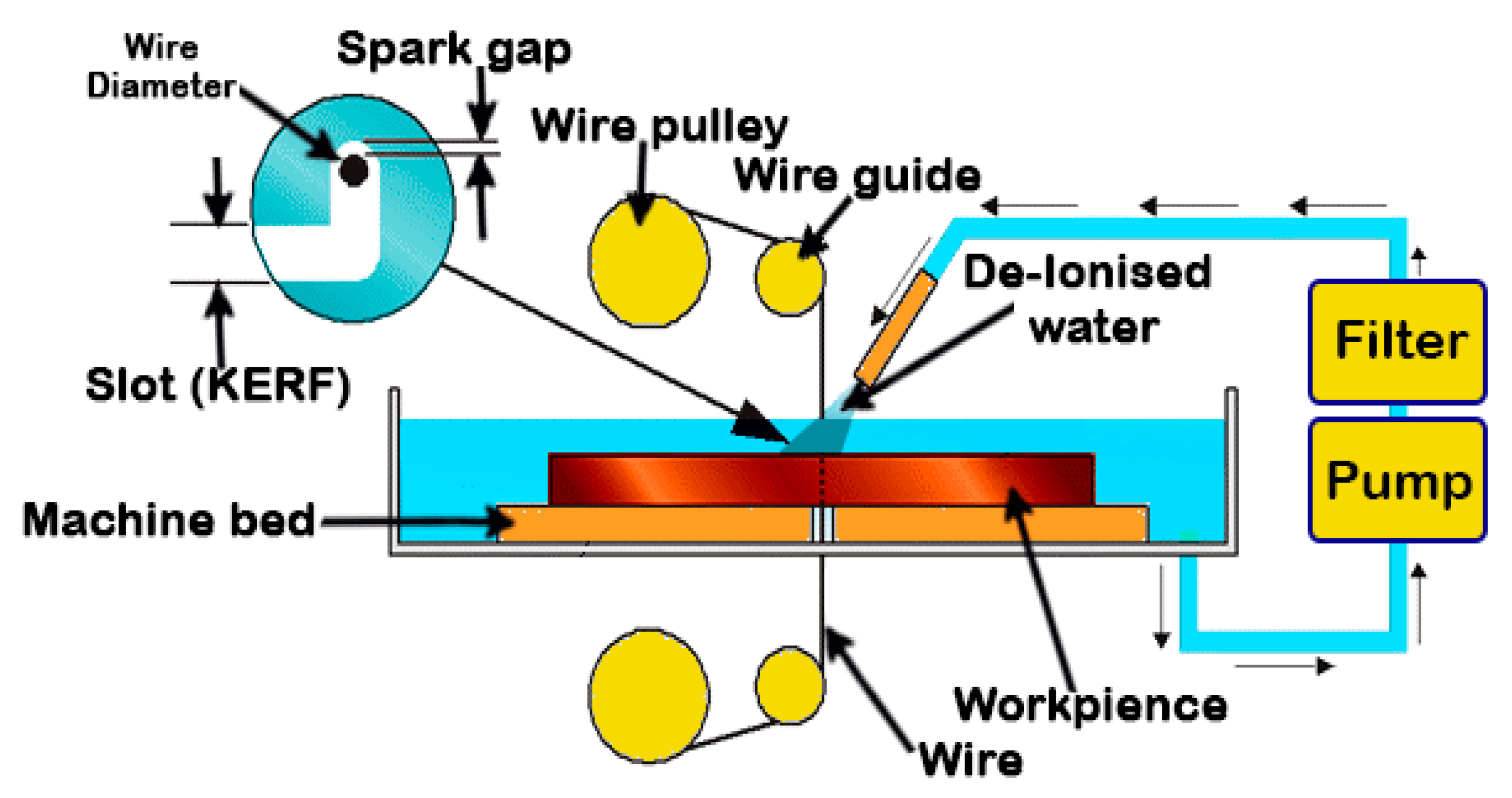

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. Ad Full suite of CNC machining services including the latest in wire EDM machining.

The tool is fed up by the Servo Feed Unit which can move. Wire EDM uses a thin wire composed of copper or brass to conduct electrical current between an electrical source and an electrically conductive base material. Principle of wire cut EDM.

It is suitable for thermoelectric. CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo. For quality parts delivered on time choose Xometry cnc machining services.

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Ad Faster processing times superior surface finishes for the most complex part geometries. One-piece solid valve lifters.

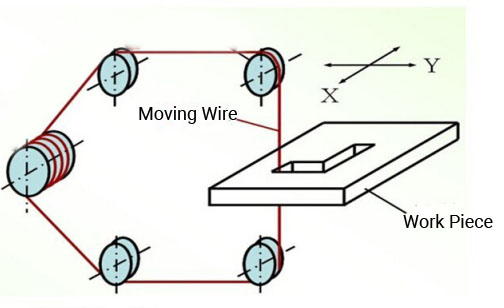

Wire edm machine working principle Tuesday June 14 2022 Edit. A non-conventional process though. The Spark Theory on a wire EDM is basically the same as that of the vertical EDM process.

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges.

Makino EDMs have a streamlined and efficient interface that helps work get done faster.

Applied Sciences Free Full Text Principles And Characteristics Of Different Edm Processes In Machining Tool And Die Steels Html

Wire Edm Cutting Process With High Precision Ruhlamat

How Does Wire Cutting Work Dienamics

What Is Edm Machining Wire Edm 101 Sans

Working Principle Of Wedm Download Scientific Diagram

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Machines Free Full Text Wire Electrical Discharge Machining A Review Html

Cnc Wire Cut Cnc Wire Edm Wire Edm Wire Edm Machine Working Principle Youtube

What Is Edm Edm Wire Products Oki Electric Cable

Wire Cut Machine 6 Basics You Need To Know Before Buying One

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Mas 865 How To Make Something That Makes Almost Anything

Sketch Of The Basic Principle Of Wire Edm Process Download Scientific Diagram

Wire Electrical Discharge Machining Also Call Wedm Its Working Principle Is The Use Of Continuous Moving Thin Wire Called Cnc Sheet Metal Cool Things To Buy

Wire Electrical Discharge Machining An Overview Sciencedirect Topics